Tungsten Electrodes Specifications Sheet 150mm--6"&175mm--7"

Summary:Tungsten Electrodes Specifications Sheet

| Type | Part # | Size (150mm-&175mm) | Applications | Alloying Element | Composition | Materials Welded |

|---|---|---|---|---|---|---|

| Pure Tungsten | ||||||

| Forms a clean, balled end when heated and provides good arc stability for AC welding with a balanced or unbalanced squarewave or sine wave. | WP040 | 0.040″ x 7″ (1.0 mm x 175 mm) | AC | None | 99.5% Tungsten 0.5% Other |

Aluminum Magnesium |

| WP116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WP332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WP018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WP532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| 2% Ceriated Tungsten | ||||||

| Performs well in DC welding and arc starting at low current settings, and can be used proficiently in AC processes. | WC040 | 0.040″ x 7″ (1.0 mm x 175 mm) | DC AC inverters |

Cerium | 97.3% Tungsten 1.8 – 2.20% Cerium 0.5% Other |

Carbon Steel Stainless Steel Nickel Alloy Titanium |

| WC116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WC332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WC018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WC532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| 1.5% Lanthanated Tungsten | ||||||

| Provides excellent arc starting, arc stability and re-ignition, and is less prone to tip wear. | WL040 | 0.040″ x 7″ (1.0 mm x 175 mm) | DC | Lanthanum | 97.80% Tungsten 1.30 – 1.70% Lanthanum 0.5% Other |

Carbon Steel Stainless Steel Nickel Alloy Titanium |

| WL116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WL332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WL018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WL532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| 2% Lanthanated (EWLa-2) | ||||||

| Substitute for 2% Thoriated. Similar characteristics to 1.5% Lanthanated with better arc starting, arc stability and less tip erosion. | WL2040 | 0.040″ x 7″ (1.0 mm x 175 mm) | DC AC inverters |

Lanthanum | 97.3% Tungsten 1.8 – 2.2% Lanthanum 0.5% Other |

Carbon Steel Stainless Steel Nickel Alloy Titanium Aluminum |

| WL2116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WL2332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WL2018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WL2532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| Rare Earth Tungsten (Non-Defined) | ||||||

| Combines the best of all alloying elements and provides excellent arc stability in AC or DC welding. | WG040 | 0.040″ x 7″ (1.0 mm x 175 mm) | DC AC inverters |

Cerium, Lanthanum, Yttrium, Others |

97.3% Tungsten Balance: Cerium, Lanthanum, Yttrium, Others |

All |

| WG116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WG332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WG018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WG532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| 2% Thoriated Tungsten | ||||||

| Offers good arc starting and is ideal for high current requirements. Also good for low-amperage AC applications using a modified point. | WT040 | 0.040″ x 7″ (1.0 mm x 175 mm) | DC | Thorium | 97.3% Tungsten 1.70 – 2.20% Thorium 0.5% Other |

Carbon Steel Stainless Steel Nickel Alloy Titanium Copper |

| WT116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WT332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WT018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WT532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

| Zirconiated (EWZr-1) | ||||||

| Balls up easily in AC applications. Handles higher current with less splitting. Improved arc starts and arc stability. Offers minimal tungsten contamination. | WZ040 | 0.040″ x 7″ (1.0 mm x 175 mm) | AC | Zirconium | 98.6% Tungsten 0.7 – 0.9% Zirconium 0.5% Other |

Aluminum Magnesium |

| WZ116 | 1/16″ x 7″ (1.6 mm x 175 mm) | |||||

| WZ332 | 3/32″ x 7″ (2.4 mm x 175 mm) | |||||

| WZ018 | 1/8″ x 7″ (3.2 mm x 175 mm) | |||||

| WZ532 | 5/32″ x 7″ (4.0 mm x 175 mm) | |||||

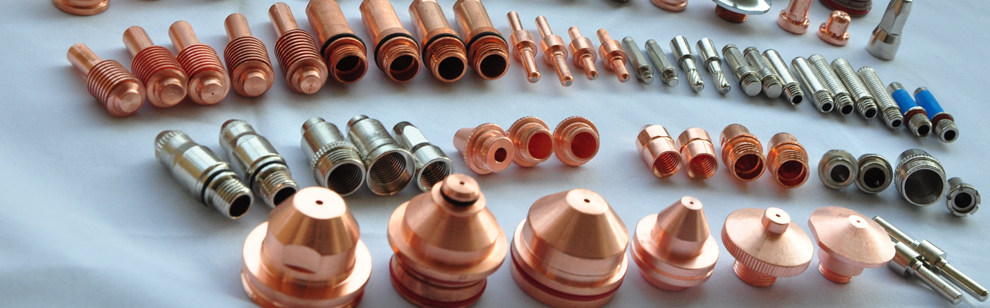

Product Catalogue

- Ceramic Nozzles (10)

- Control Wire Plugs (1)

- Power Cable Adapters (5)

- Gas Lens (5)

- Collet Bodies (4)

- Collets (6)

- Back Caps & Valve Stems (9)

- Plugs and Sockets (9)

PLASMA Cutting Tips (56)

- Panasonic (2)

- Plasma (0)

- KOIKE (4)

- KJELLBERG (14)

- THERMAL DYNAMICS (6)

- KOMATSU (1)

- TRAFIMET (6)

- BINZEL (5)

- CEBORA (3)

- ESAB (3)

- OTC (2)

- SAF (1)

- JG-100 (2)

- SG-123 (1)

- SG-51 (1)

- JG-250 (1)

- FANYANG (4)

Earth Clamp (7)

Electrode Holder (24)

Gas Regulator (65)

Products Search