Brief History

Tungsten inert gas (TIG / GTAW) and metal inert gas (MIG / GMAW) welding are both welding techniques developed in the early 1940’s in response to increased demand for weaponry. TIG was primarily developed for the aircraft industry while MIG was developed to increase the speed of weapon production.

Basics

TIG welding uses a tungsten electrode that is not consumed during the welding process. TIG welding uses argon, a mix of argon and hydrogen, or an argon and helium gas mix to provide shielding. TIG welding is recommended for materials such as magnesium, aluminum and copper alloys, and thin pieces of stainless steel.

On the other hand, MIG welding works well on steels because it is one of the fastest types of welding processes available. MIG welding uses a metal electrode that doubles as filler material for the weld and is consumed during the process. In MIG welding, argon gas is used alone or in combination with oxygen, carbon dioxide, or helium.

Benefits of TIG Welding

Produces better quality welds

Welder has precise control of the heat of the electrode, which causes fewer distortions

No splatter produced

Welds can be made with or without filler metal

Has a lower deposition rate

Benefits of MIG Welding

Longer welds without stops and starts increase productivity

Cheaper welders

Easier to learn and good for home use

Less cleanup required

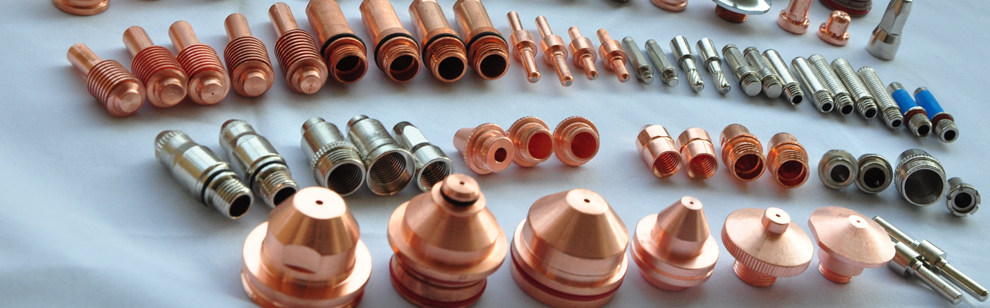

- Ceramic Nozzles (10)

- Control Wire Plugs (1)

- Power Cable Adapters (5)

- Gas Lens (5)

- Collet Bodies (4)

- Collets (6)

- Back Caps & Valve Stems (9)

- Plugs and Sockets (9)

- Panasonic (2)

- Plasma (0)

- KOIKE (4)

- KJELLBERG (14)

- THERMAL DYNAMICS (6)

- KOMATSU (1)

- TRAFIMET (6)

- BINZEL (5)

- CEBORA (3)

- ESAB (3)

- OTC (2)

- SAF (1)

- JG-100 (2)

- SG-123 (1)

- SG-51 (1)

- JG-250 (1)

- FANYANG (4)